Warshada si toos ah Shiinaha Single Plastic Extruder

Furaha guusha our waa "Good Badeecada tayo sare leh, Qiimaha Iibinta macquulka ah iyo Adeegga hufan" ee Factory si toos ah Shiinaha Single Plastic Extruder, We sincerely hope to build some accusfactory associations along with you from the close to long.Waanu idinla socodsiin doonnaa horumarkayaga, waxaanan kula socon doonnaa dhisidda xidhiidh joogto ah oo ururrada ah.

Furaha guushayagu waa "Adeecada Wanaagsan ee Tayada Sare leh, Qiimaha Iibinta macquulka ah iyo Adeeg hufan"Shiinaha Extruder, balaastig ah, Sababtoo ah shirkadeena ayaa ku adkaysatay fikradda maareynta ee " Badbaadinta Tayada, Horumarinta Adeegga, Faa'iidada Sumcada" .Waxaan si buuxda u ogaanay heerka credit ee wanaagsan, alaabta tayada sare leh, qiimaha macquulka ah iyo adeegyada xirfada leh ayaa ah sababta ay macaamiishu noo doortaan inaan noqono lammaanahooda ganacsi ee mudada dheer.

Fiidiyowga Alaabta:

Habaynta Sawirada Qalabka:

Qalabka Habaynta:

HDPE, LDPE, LLDPE, PP, sida filimada, bacaha, jajabka, rollers film, filim fidsan, filim yar yar, filim lakabyo badan, boorso funaanad gooyay

Xumbo leh PE, EPS iyo XPS: duub, boorso, xaashi, weel cunto, shabag miro, dabool

Dharka: PP fiber, raffia, xariir, dun, bac tolan, bac jumbo

Astaamaha:

Nidaamkan isku-dhafka ah ee loo yaqaan 'pelletizing compactor' wuxuu faa'iido u leeyahay walxaha dib loo warshadeeyay iyada oo aan horay loo jarin

Isku-duubni waxa lagu qalabeeyaa baallayaasha gooya, kuwaas oo loo isticmaalo xakamaynta xawaaraha quudinta alaabta

Nidaamka faakuumka si uu u daayo biyaha ama gaaska ilaa xad

Shayga shaandheynta Haydarooliga heer sare ah oo leh cadaadis deggan oo aan joogsanayn, wax daadanaynin

Badbaadinta tamarta oo leh wax soo saar sare (0.28kwh/kg)

Habka guud ee shaqada:

1.Waxyaabaha gudbinta suunka ee wareejinta suunka oo la jeexjeexay.

2.Nidaamka kontoroolka isku xidhka ee udhaxeeya gudbinta suunka iyo jajabinta compactor-ka waxay xaqiijisaa quudinta dheellitirka iyada oo aan lahayn compactor dhalaalay.

3. Xagga hoose ee compactor shredding, waxaa jira hal loox gooyay.iyadoo leh xooga centrifugal, walxaha dib loo warshadeeyay ayaa horay loo gooyay goynta gudaha iyo gooyayaasha taagan.

4.Inta ka dib, walxuhu wuxuu galaa qulqulka degeyska ee dhinaca is haysta.

5.With kuleyliyaha fur, balaastiig waxay noqotaa wax semi-plastification ah.

6. Ka dibna, walxaha semi-caaga ah ayaa la gooyaa pellets.

Halbeegga Farsamo ee ugu Muhiimsan:

| Qaabka | ML75B | ML85B | ML100B | ML130B | ML160B | ML180B |

| Dhexroor maroojin (mm) | 75 | 85 | 100 | 130 | 160 | 180 |

| L/D | 26 ilaa 37 | |||||

| Wax soo saarka (kg/h) | 100-150 | 200-350 | 400 ilaa 550 | 600 ilaa 800 | 800 ilaa 1000 | 1000-1200 |

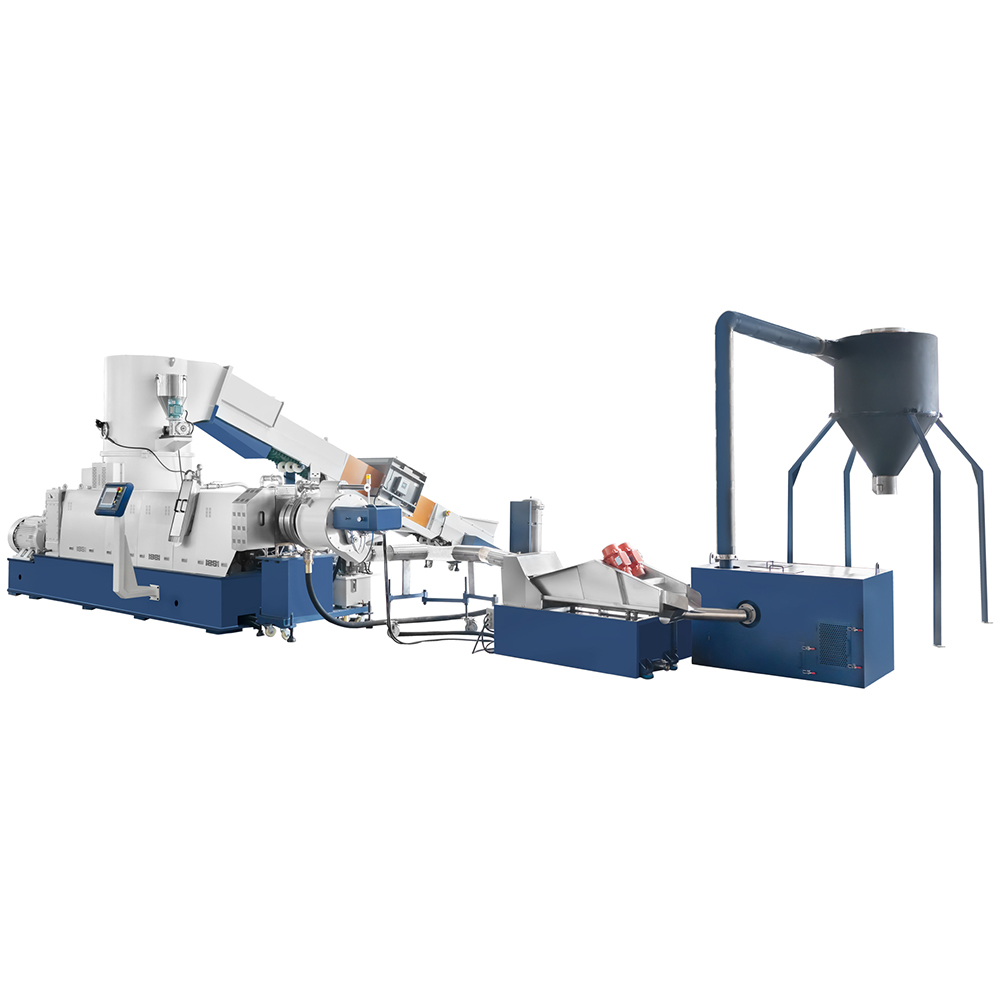

Sawirada Mashiinka:

Kaaliyaha kali ah

Dib-u-warshadaynta dib-u-warshadaynta laba jeer

Warbixin guud:

| Magaca model | ML |

| wax soo saarka | Pellets caaga ah/granules/resin/caag cayriin ah |

| Qaybaha mashiinka | Gaadhida suunka, qalabka wax gooya, duuliyaha ugu weyn, unugga pelletizing, nidaamka qaboojinta, silo, armaajo |

| Walxaha dib u warshadaynta | Filimka PP/PE/LDPE/HDPE, bac, fiber |

| Kala duwanaanta awoodda | 100kg/h ilaa 1200kg/h |

| Habka quudinta | Gaadhi, habka wadista duubka |

| Dhexroor maroojin | 75mm ilaa 200mm |

| Isku dhufashada L/D | 26 ilaa 33 |

| Marooji alaabta ceeriin | 38CrMoAl ama bimetallic |

| degenaansho | Degsi dabiici ah, vacuum degassing |

| Nooca goynta | Habka pelleting toosan, jiid pelleting xariijimaha |

| Nooca qaboojinta | Biyo qabow, hawo qabow |

| danab | La habeeyay |

| Qalabka ikhtiyaariga ah | Qalabka birta, nidaamka qaboojinta biyaha, silo quudinta, nidaamka gariir |

| Waqtiga dirida | 40 ilaa 60 maalmood |

| Waqtiga dammaanadda | 13 bilood |

| Taageerada farsamada | Nashqada mashiinka, qaabka rakibida, adeegga injineernimada |

| Shahaado | CE/ SGS/ TUV/CO |

Maxaa noo doora?

A.PURUI waxay leedahay soo saaraha xirfadle tan iyo 2006. waxaan leenahay waaxda naqshadeynta farsamada noo gaar ah.Extruder kasta waxaa loo qaabeeyey si waafaqsan sifada alaabta.

B.Awood kaydinta oo leh wax soo saar sare

C.Waqtiga dammaanadda tayada tayada leh waa 12 bilood laga soo bilaabo taariikhda Bill of Lading.

D. Wakhtiga bixinta: 40 maalmood oo shaqo ilaa 60 maalmood

E.Markab baa la codsaday

Ku rakibida F.Machine waa la heli karaa.Waxay qaadataa qiyaastii 5 ilaa 7 maalmood iyadoo la dhammaystirayo hal mar oo rakibid ah.Injineerada loo xilsaaray ayaa maamula tababarka isticmaalaha mishiinka, hawlgalka mashiinka iyo komishanka.

Hordhaca Shirkadda:

Chengdu PuRui Polymer Engineering Co. Ltd waa mid ka mid ah soosaarayaasha ugu horreeya ee mashiinnada dib-u-warshadaynta caagga ah, extruder, granulator caag ah iyo qalab caawimo ah oo la xidhiidha Shiinaha.Nidaamkeena pelletizing caaga ah faa'iidooyinka gaarka ah waa naqshadeynta birta, wax soo saarka sare, degeyska wanaagsan iyo saamaynta shaandhada wanaagsan.Khadkayaga caagga ah ee lagu dhaqo sida burburiyaha leh caabbinta fiiqan iyo gooyo fiiqan, cutubyada dharka, kala-soocidda ama mashiinka kala-soocidda, nidaamka qalajinta, iyo nidaamka baakadaha ayaa ah tayada codka. Furaha guushayadu waa "Badeeco Wanaagsan oo tayo sare leh, Qiimaha iibka macquulka ah iyo Adeeg hufan" ee Factory si toos ah Shiinaha Single Plastic Extruder Twin caag Screw Extruder, Waxaan si daacad ah rajaynaynaa in la dhiso qaar ka mid ah ururada ku qanacsan oo ay la socdaan aad ka dhow mustaqbalka fog.Waanu idinla socodsiin doonnaa horumarkayaga, waxaanan kula socon doonnaa dhisidda xidhiidh joogto ah oo ururrada ah.

Warshada si toos ahShiinaha Extruder, Plastic Extruder, sababtoo ah shirkadeena ayaa ku adkaysatay fikradda maareynta ee " Badbaadinta Tayada, Horumarinta Adeegga, Faa'iidada Sumcada" .Waxaan si buuxda u ogaanay heerka credit ee wanaagsan, alaabta tayada sare leh, qiimaha macquulka ah iyo adeegyada xirfada leh ayaa ah sababta ay macaamiishu noo doortaan inaan noqono lammaanahooda ganacsi ee mudada dheer.

Mashiinka dib-u-warshadaynta caagga ah iyo granulation-ka waa nooc ka mid ah qalabka loo isticmaalo dib-u-warshadaynta qashinka caagga ah ee loo yaqaan granules ama pellets kuwaas oo dib loogu isticmaali karo soo saarista alaab cusub oo caag ah.Mashiinku wuxuu caadi ahaan u shaqeeyaa isagoo jarjaraya ama shiidaya qashinka balaastiigga ah qaybo yaryar, ka dibna dhalaalay oo ka soo saaraya dhinta si ay u sameeyaan pellets ama granules.

Waxaa jira noocyo kala duwan oo dib-u-warshadaynta balaastiigga ah iyo mishiinnada granulating, oo ay ku jiraan kuwa kaashashka ah iyo kuwa mataanaha ah.Mashiinnada qaarkood waxa kale oo ay ku jiraan sifooyin dheeraad ah sida shaashadaha si looga saaro wasakhda wasakhda caaga ah ama hababka qaboojinta si loo hubiyo in pellets-ku si fiican u adkeysteen.Mashiinka dhaqda dhalada ee PET, khadadka dhaqida bacaha tolan ee PP

Mashiinnada dib-u-warshadaynta caagga ah iyo granulation-ka ayaa caadi ahaan loo adeegsadaa warshadaha soo saara xaddi badan oo qashinka caagga ah, sida baakadaha, baabuurta, iyo dhismaha.Dib-u-warshadaynta qashinka balaastikada ah, mashiinadani waxay kaa caawinayaan yaraynta saamaynta deegaanka ee qashinka balaastigga ah waxayna ilaalinayaan agabka iyagoo dib u isticmaalaya agabka haddii kale la tuuri lahaa.

Qalabka dib-u-warshadaynta baytariyada Lithium waa nooc ka mid ah qalabka loo isticmaalo dib-u-warshadaynta iyo dib-u-soo-celinta alaabta qiimaha leh ee baytariyada lithium-ion, kuwaas oo inta badan loo isticmaalo qalabka elektaroonigga ah sida casriga, laptops, iyo baabuurta korontada.Qalabku wuxuu caadi ahaan u shaqeeyaa isagoo u kala jejebiya baytariyada qaybahooda ka kooban, sida maadada cathode iyo anode-ka, xalalka elektrolytka, iyo foils-ka birta ah, ka dibna kala sooca oo nadiifiya alaabtan si dib loogu isticmaalo.

Waxaa jira noocyo kala duwan oo ah qalabka dib u warshadaynta ee baytariyada lithium, oo ay ku jiraan hababka pyrometallurgical, hababka hydrometallurgical, iyo hababka farsamada.Nidaamyada pyrometallurgical waxay ku lug leeyihiin habaynta heerkulka sare ee baytariyada si loo soo celiyo biraha sida naxaasta, nikkel, iyo kobalt.Nidaamyada Hydrometallurgical waxay isticmaalaan xalal kiimiko si ay u milmaan qaybaha baytariyada oo ay ka soo kabtaan biraha, halka hababka farsamaysan ay ku lug leeyihiin jajabinta iyo shiididda baytariyada si ay u kala soocaan alaabta.

Qalabka dib-u-warshadaynta baytariyada Lithium waxay muhiim u tahay yaraynta saamaynta deegaanka ee daadinta batteriga iyo ilaalinta kheyraadka iyadoo dib loo soo celinayo biraha iyo alaabta qiimaha leh ee dib loogu isticmaali karo baytariyada cusub ama alaabada kale.

Marka laga soo tago faa'iidooyinka ilaalinta deegaanka iyo kheyraadka, qalabka dib-u-warshadaynta baytariga lithium wuxuu kaloo leeyahay faa'iidooyin dhaqaale.Ka soo kabashada biraha iyo alaabta qiimaha leh ee baytariyada la isticmaalay waxay yarayn kartaa kharashka soo saarista baytariyada cusub, iyo sidoo kale abuurista dakhli cusub oo loogu talagalay shirkadaha ku lug leh habka dib u warshadaynta.

Intaa waxaa dheer, baahida sii kordheysa ee baabuurta korontada iyo qalabka kale ee elektiroonigga ah ayaa horseedaya baahida loo qabo warshadaynta dib-u-warshadaynta batteriga oo hufan oo waara.Qalabka dib-u-warshadaynta baytariyada Lithium waxay kaa caawin kartaa buuxinta baahidan iyagoo siinaya hab la isku halayn karo oo kharash-ool ah si looga soo kabsado alaabta qiimaha leh ee baytariyada la isticmaalay.

Si kastaba ha ahaatee, waxaa muhiim ah in la ogaado in dib-u-warshadaynta baytariyada lithium ay wali tahay warshad cusub, waxaana jira caqabado laga gudbi karo marka la eego horumarinta hababka dib-u-warshadaynta waxtarka leh ee waxtarka leh.Intaa waxaa dheer, in si sax ah loo maareeyo loona tuuro qashinka batteriga ayaa muhiim ah si looga fogaado khataraha deegaanka iyo caafimaadka.Sidaa darteed, xeerar sax ah iyo tillaabooyinka badbaadada waa in la sameeyaa si loo hubiyo maaraynta mas'uuliyadda leh iyo dib u warshadaynta baytariyada lithium.